Bridgestone Corp is the world’s largest manufacturer or tyres and other rubber products. Headquartered in Tokyo, Japan, the brand apart from tyres, also manufactures industrial rubber and chemical products, sporting goods, and other diversified products.

In Malaysia, Bridgestone Tyre Sales Malaysia is an affiliate of Bridgestone Corp and was set up in 2000 to provide exceptional customer service and provide quality products for Malaysians. We speak to Joe Takekawa, Managing Director for Bridgestone Malaysia on the status of the brand within the region, partnerships and sustainability.

You have a few range of tyres for passenger cars, mainly Potenza, Turanza and Ecopia among others. Where are the standings for each model, and how does each model contribute in total sales for Bridgestone SEA or APAC?

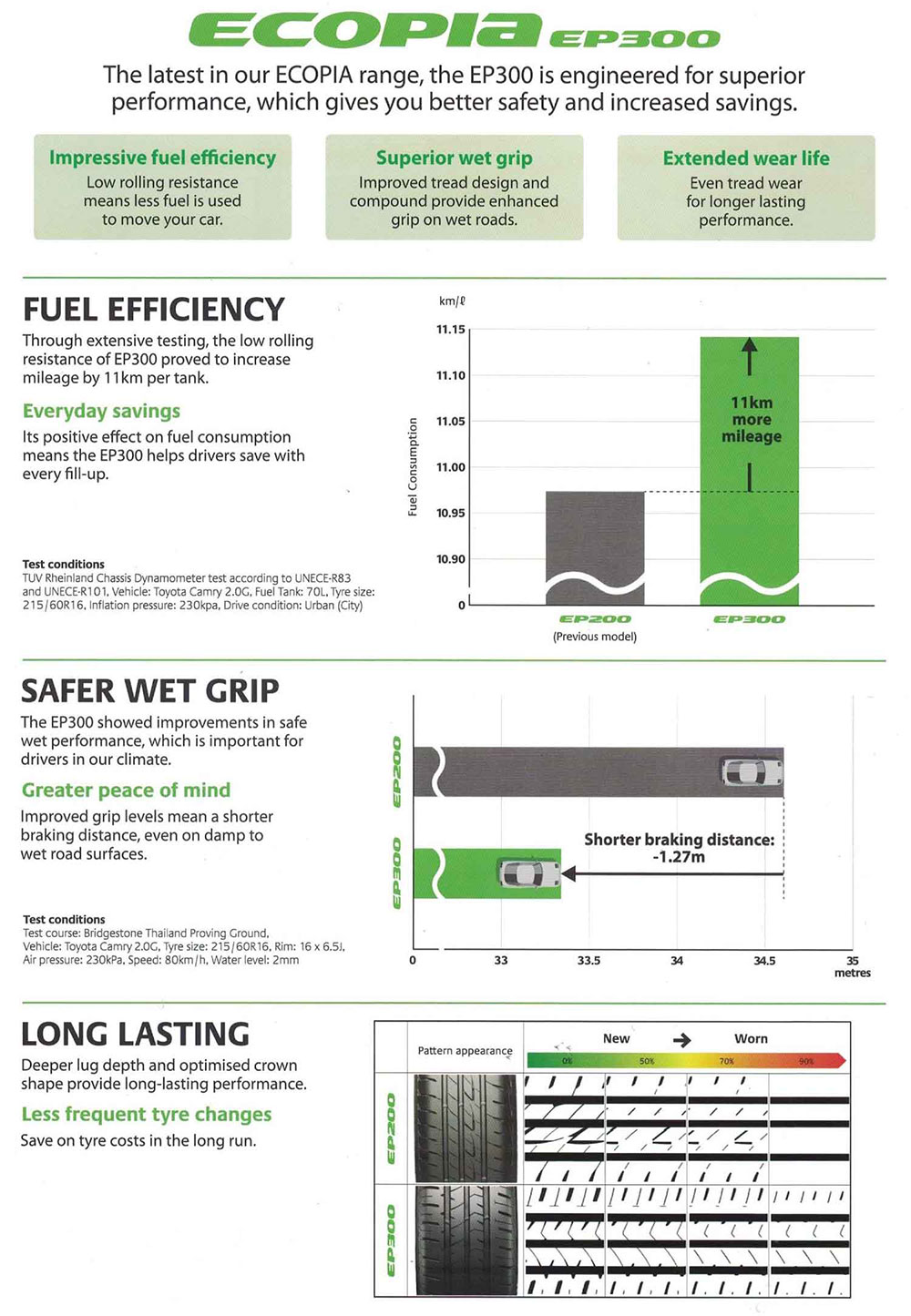

JT: I would say ECOPIA tyres contributes the most in total sales for Bridgestone Asia Pacific markets. When ECOPIA was first launched in Asia Pacific in 2009, it was a new brand consisting of a single product, and made up 2% of the region’s passenger car tyre sales.

From 2012 to 2013 new ECOPIA products targeting a wider range of vehicles were introduced, leading to ECOPIA making up more than 20% of the region’s replacement passenger tyre sales. Five years following its launch, ECOPIA passenger car tyres achieved sales of more than 10 million in the Asia Pacific region.

Bridgestone in terms of global ranking, comes up top compared to other brands. What do you think contributes to the success of the company to make it a market leader?

JT: Bridgestone operates businesses around the world and covers a broad range of business activities in multiple sectors. All these business activities are connected and demand consistency between Global/Regional strategies, while offering a unique portfolio of opportunities to develop initiatives that secure our competitive advantage not only in short-term but also in the mid-to-long term.

Through these opportunities and initiatives, we have identified four basic pillars on which to build up our competitive advantage in the China and Asia-Pacific Region. They are Brand, Business operations including go-to-market aggressive channel strategies, People and Corporate Social Responsibility. Let me take this opportunity to dwell a bit on two of them: Brand and People.

Brand: Our strong commitment is to deliver our Brand promise in terms of products, services, and quality. The focus will be always on end-users/customers’ requirements and expectations, with the target of creating added value for them through continuous innovation. In doing so we will capitalize our Brand portfolio (Bridgestone, Firestone, Dayton) by tailoring the relevant balance of performance-to-cost ratio in line with market segmentation.

To promote our products and services portfolio, we will also leverage the tremendous platform provided by our Olympic Top Partnership status contracted with the International Olympic Committee until year 2024 (We are the first and only Tyre & Rubber Company in the history so far). We already have in the pipeline initiatives and plans that will communicate a strong and effective brand message that will resonate across the Asia-Pacific region.

People: Leadership style and Talent Management development are at the top of our agenda. We must have the right people on board and the right people on the right seats. The development of local talents to become capable of global management will also be in the forefront of our HR strategy. We are committed to capitalizing on the incredibly rich diversity that this region offers by promoting tailored training and education programs, while progressively assigning regional talents to key positions within the organization.

Bridgestone has been popular supplying tyres for Formula 1 since the 90s and stopped in 2010. As of currently, the brand’s only motorsport participation is in the Super GT championship. Are they any plans to continue motorsport participation of any sort? Both globally or through local races in Malaysia?

JT: Bridgestone supports numerous teams, drivers, and riders in a variety of events from top-level races to grassroots motorsports. Among branding and marketing initiatives through various sports events, Bridgestone views motorsports as an important communication platform that is directly linked to its tyre business. Participating in motorsports, Bridgestone aims to create higher competitive tyres while working together with car and motorcycle manufacturers and other related parties to contribute to the development of the automobile industry and motorsport culture.

Through on-track knowledge and experience during tough and competitive top-level races, Bridgestone is able to enhance its tyre development capability.

In Japan, Bridgestone will supply tyres to teams competing in the SUPER GT for cars as well as in the All Japan Road Race Championship and the Suzuka 8hours Endurance Race for motorcycles. Bridgestone will also supply tyres to teams participating in FIM* Endurance World Championship series (EWC) which is the world’s foremost series of endurance motorcycle races held in Europe and Japan.

In addition, as the official tyre supplier, Bridgestone will continue to provide Firestone brand tyres to the IndyCar Series in North America.

Bridgestone also supports various grassroots motorsports, including the TOYOTA GAZOO Racing 86/BRZ Race, the ROADSTER Party Race III, and gymkhana races.

These are examples of Bridgestone’s activities to increase the number of car fans. Through these grassroots motorsports, Bridgestone hopes to deliver enjoyable driving experiences. Moreover, Bridgestone continues to supply tyres to cars competing in Nürburgring 24 Hours Endurance Race held in Germany that gathers crowds of more than 200,000 spectators.

Bridgestone will primarily supply POTENZA brand tyres for car races and BATTLAX brand tyres for motorcycle races in pursuit of collaborative victory with teams, drivers, and riders.

Also in 2017, Bridgestone continuously supports the Bridgestone World Solar Challenge (October 8 to 15), a solar car race of teams from around the world competing on a route that spans across Australia. The company provides environmental technologies to support the student engineers taking part in this grueling race, which covers a 3,000 km course stretching from the north to the south of Australia.

Tyres are quite a difficult product to recycle. As a tyre company that has a focus on environmental concerns, what are Bridgestone’s efforts to improve tyre waste? Are there interests to produce a tyre based on previous recycled tyres?

JT: It is projected (by the WBCSD Tyre Industry Project) that approximately one billion used tyres will emerge worldwide each year. Reducing the environmental impact of used tyres is a common issue within the tyre industry.

Bridgestone has been involved in the Tyre Industry Project of the World Business Council for Sustainable Development (WBCSD), which was established in 2006. As the tyre and rubber company, the Company has worked toward building a sustainable society in cooperation with other companies in the industry. This project aims to develop an effective management system for used tyres by encouraging related industries and governments in various countries to appropriately manage used tyres and reduce their environmental impact through the publication of “End-of-Life Tyres (ELT): A Framework for Effective ELT Management Systems” and disclosure of survey results.

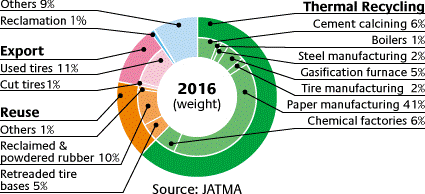

Japan Automobile Tyre Manufacturers Association (JATMA) and many others in the tyre industry are working toward reducing (controlling the emergence of used tyres) and recycling used tyres, which is vital for the development of a society that recycles. More specifically, they implement monitoring of reduction factors focusing on making tyres lighter and longer lasting, monitoring of tyre recycling status and measures against illegal accumulation and dumping of waste tyres. According to a JATMA survey, the 2016 recycling rate of used tyres in Japan was 91%. Bridgestone contributes to reducing the environmental impact of used tyres in Japan through joint activities with JATMA.

Projects in this region

Operation of Facilities Oriented toward Recycling of Used Tyres

Bridgestone Tyre Japan Co., LTD. (BTJ) operates the Bridgestone Tyre Recycle Center Osaka. The center combines functions of a retread tyre*1 manufacturing facility and an intermediate used tyre*2 treatment facility in a single location, and it enables collection*3 of customers’ used tyres, and reuse and recycling of all collected tyres. The center won the 3R (Reduce, Reuse, Recycle) Promotion Council President’s Prize at the Fiscal 2015 3R Promotion Merit Awards in Japan. We will continue to work to use resources in a more sustainable way.

Tyres that are reused by replacing tread rubber

Crushing of waste tyres that cannot be re-tread

Collection areas include Osaka Prefecture and parts of Kyoto, Hyogo, Shiga and Wakayama Prefectures The Group also collects discarded tyres in accordance with established laws/regulations and procedures.

Australia / New Zealand: Tyre Recycling – More Important Than You Think

At Bridgestone, we take the responsible disposal of end-of-life tyres very seriously and are 100% committed to helping increase the rate of tyre recycling here in Australia. And when so many useful things can be created using recycled tyres, why wouldn’t you?

Recycled tyres are often used to replace, enhance or extend the quality of materials across many markets including:

Running tracks and sporting grounds – Incorporating recycled rubber into running tracks assists with impact absorption, increases performance and reduces injury risks. It can also be placed under synthetic grass on sporting grounds, making it a softer place to fall.

Brake pads – Thanks to some relatively new technology now available in Australia, recycled rubber crumb can be repurposed to produce asbestos-free brake pads. These aren’t as noisy and have improved wearability.

Building insulation – For building purposes, recycled granulated rubber can be rolled into noise-reducing insulation. It’s commonly used in units and apartments, both under flooring and in the walls.

Matting and non-slip surfaces – A range of hard-wearing, long lasting matting products can be made from recycled rubber, including non-slip door mats and commercial workshop and kitchen mats. Recycled rubber granules can also be used to create marine non-slip surfaces, such as walkways on boats.

Civil engineering – Recycled tyres are often used in civil engineering jobs, such as road and drain construction. Producing road surfaces using recycled rubber improves performance, reduces noise and increases the life span of our roads.

Fuel for energy recovery – Recycled rubber can be used to power the production of cement, steel and even paper!

Looking to get a new car? Trade in your car for that one you’ve been eyeing!